Fluid contaminants are often invisible to the naked eye, as is the danger they pose. Because contamination is often the cause of machine failures. It usually starts harmlessly, but contamination quickly destroys the fluids’ lubricating and protective properties. The result: increased oil consumption, corrosion, cavitation and increased component wear. This leads to unnecessary service calls and a larger carbon footprint.

1st tip: coalescing

Coalescers work efficiently with free & emulsified water

When it comes to removing free and emulsified water from hydraulic oils, our coalescers are ready to assist you.

Small water droplets from the emulsion adhere to the coalescing element fibers. Coalescence with other droplets on the fibers or the fiber nodes causes them to combine to form larger droplets. These are separated in the housing by gravity or by gravity along with the use of a special separating element. The water collects at the bottom of the housing and is drained by opening a valve.

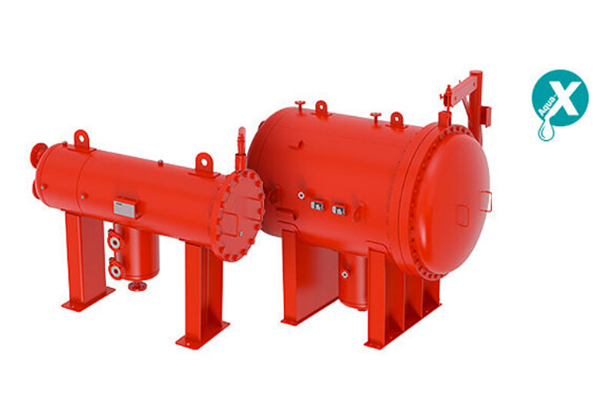

2nd tip: dewatering & degassing

Vacuum method: removing water & gases without damaging oil

A dry air stream meets moist oil in the vacuum column. This transfers the water from the hydraulic oil to the air and dries the oil. The vacuum separates free and dissolved gases/air. Before the hydraulic oil leaves the unit, particles are removed by a particle filter.

Our FAM units are all-rounders when it comes to dewatering and degassing. They remove solid contamination, free and dissolved water and gas from hydraulic oil. They have been used successfully in many different applications for more than 30 years and are characterized by their reliability and durability.

3rd tip: superabsorbents

Higher cleanliness levels: these filter elements bind water

The Aquamicron filter elements are the ideal solution when it comes to eliminating residual water in small tanks (after an oil change, for example).

The Aquamicron filter elements convert free water into a highly viscous gel (superabsorbent). The filter layer on the downstream side prevents the gel from getting into the oil. The bound water cannot be released again even with increased pressure. The superabsorbent is insoluble in mineral oils and synthetic esters.