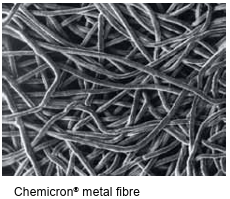

In polymer melt processing, the quality of filtration directly affects the purity and performance of the final product. Applications such as film extrusion, fiber spinning, and compound production require filter media that can withstand high temperatures, retain fine contaminants, and operate reliably over time. Engineered specifically for demanding applications, Chemicron® delivers exceptional filtration efficiency, thermal resistance, and durability far beyond conventional media like wire mesh or sintered powder.

What Is Chemicron®?

Chemicron® is a multi-layered sintered metal fiber fleece, typically made from high-grade stainless steel (AISI 316L). It combines the structural benefits of a rigid metallic filter with the depth-filtration capabilities of a nonwoven media.

Its key characteristics include:

- Fiber diameters as fine as a few microns

- Porosity up to 90%

- Multi-layer structure for graded filtration

- Thermal and mechanical stability up to 400 °C

- Pressure resistance up to 210 bar (differential)

Advantages of Chemicron®

1. High Filtration Efficiency

Chemicron® provides depth filtration, not just surface filtration. This means contaminants are trapped throughout the media’s thickness—not just on its surface—resulting in:

- Reliable removal of fine particles down to 1 µm

- Capture of soft contaminants like gels and agglomerates

- Cleaner polymer melt with improved end-product quality

2. Low Pressure Drop

Thanks to its high porosity (up to 90%), Chemicron® enables:

- Smooth flow of high-viscosity melts

- Lower energy consumption during extrusion or molding

- Reduced wear on pumping and dosing equipment

3. High Dirt-Holding Capacity

The depth structure allows Chemicron® to retain more contaminants before clogging, which leads to:

- Longer operating cycles

- Fewer filter changes

- Lower maintenance and downtime

4. Thermal and Chemical Resistance

Chemicron® operates under extreme conditions:

- Up to 400 °C continuous temperature

- Maintains structural integrity under high mechanical stress

5. Cleanability & Reusability

Unlike disposable polymer filters, Chemicron® elements can be:

- Backflushed

- Ultrasonically cleaned

This results in lower total cost of ownership and more sustainable operations.

6. No Media Migration

Unlike glass fiber or polymeric media, Chemicron®:

- Does not shed fibers into the melt

- Ensures ultra-clean filtration for high-purity polymers (e.g., medical-grade or optical applications)

Chemicron® in Polymer Applications

Chemicron® is ideally suited for filtering high-performance polymers, including:

- Polypropylene (PP) and Polyethylene (PE) melts

- Polyester (PET) fibers

- Nylon (PA) and Polysulfone (PSU) for medical and automotive use

- Epoxy resins, PU, and polyol systems for coatings and adhesives